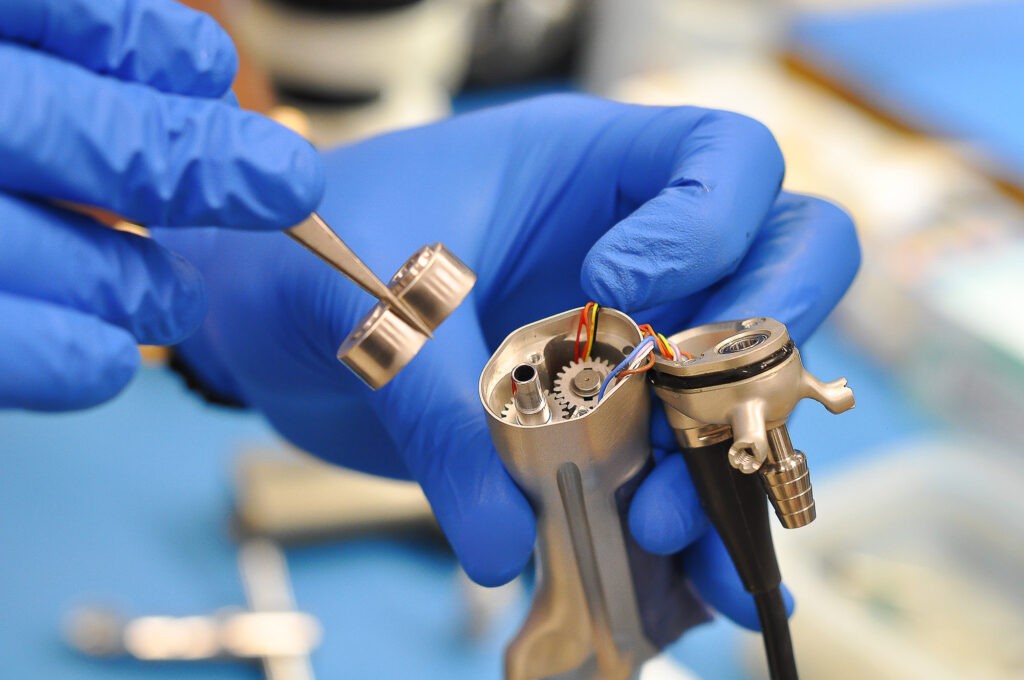

Getting your power tools repaired quickly is important. Ensuring they return to your OR and function with precision and consistency is vital to long-term operational and financial outcomes. Whether you need a simple repair or a total rebuild, our technicians utilize proprietary tools and techniques to diagnose, repair and test all equipment prior to sending it back to you to ensure it is operating to the highest level. All services follow strict quality control standards* and are backed by warranties on service performed. We also offer a variety of maintenance and service packages designed to maximize power tool performance while reducing service costs.

Addler provides onsite and depot-model services to support pneumatic and electric or battery-operated devices — even for items the manufacturer has tagged as non-repairable. Our repair services range from basic repair to total rebuilds on items such as:

Onsite preventive maintenance is also available for pneumatic and electric/battery devices.

Our full-service capabilities also include Phaco device rebuilds such as:

Your hospital can’t stop just because a power tool device is broken. That’s why we provide free loaners while we repair your surgical technology. We maintain an extensive loaner collection to meet our customers’ preferences and prevent any disruption to planned procedures.

Ensuring every piece of equipment meets its optimal device performance is a key driver in our quality process. We do this by performing a thorough inspection for every power tool we touch using proprietary surgical power tool testing equipment. But we do more than just inspect. At Addler, we execute precise testing and adhere to rigorous parts sourcing, compatibility and traceability to ensure our customers receive only the highest quality parts and craftsmanship.

The result? Your surgical power tools will return quickly, deliver consistent performance and function optimally.

Golden Nimbus Pvt. Ltd. G-4, Sangeet Plaza, Near SBI, Marol Naka, Metro Station, Marol Maroshi Rd, Andheri(East), Mumbai, Maharashtra 400059

Copyright © 2021 by ADDLER. All rights reserved.